Smart Gasifiers

The World is in a RUT

The world’s “Resource Utilization Trajectory” (RUT) is an unsustainable downcycling economy.

Products from irreplaceable fossil fuels are often used once and thrown away. Synthetic polymers resist degradation and can persist for decades, even centuries. The world’s poorest nations suffer the most from waste accumulation, even though they use the least resources per capita. Pollution of the land, air and sea is a global problem that can no longer be ignored.

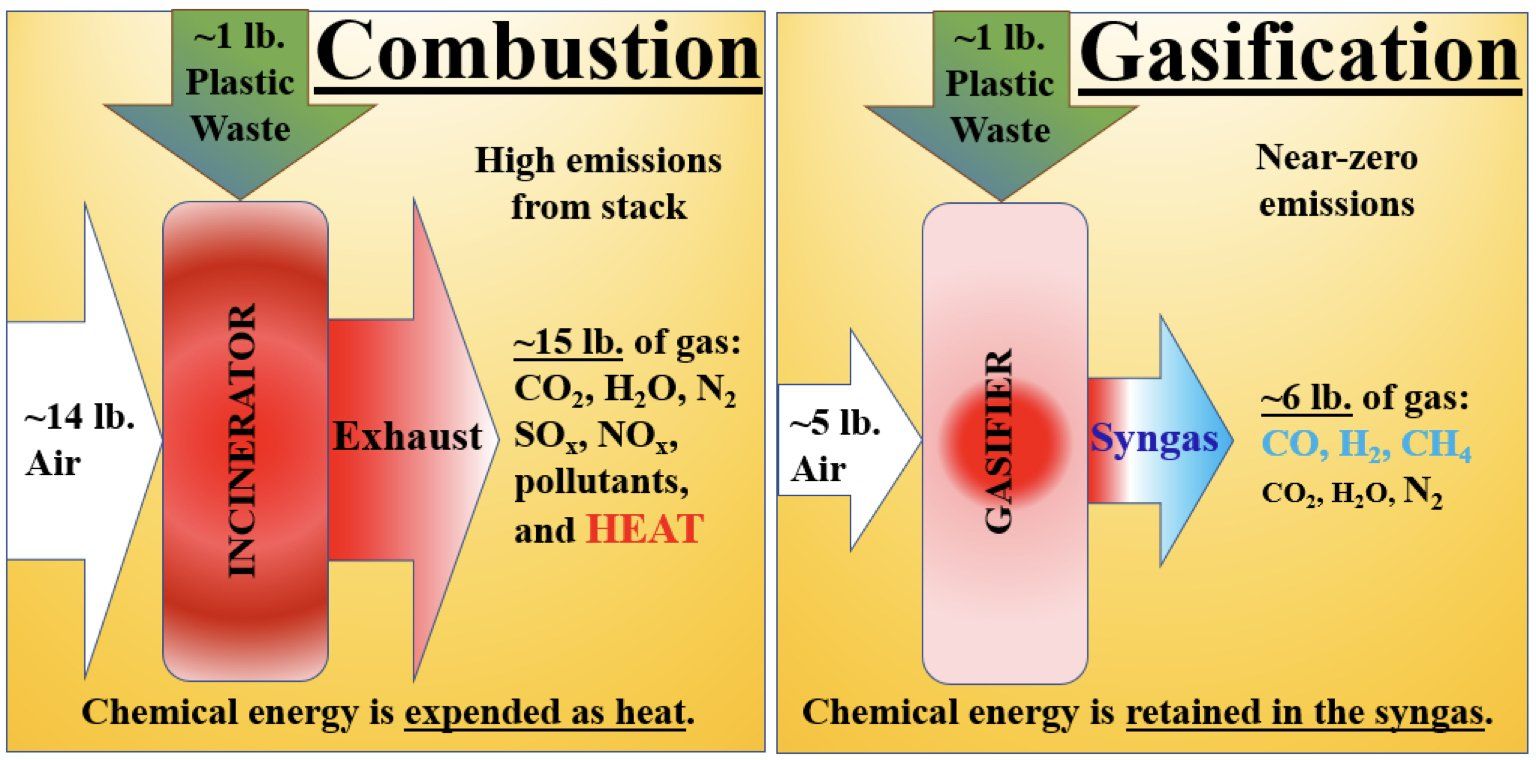

Comparison of Combustion vs. Gasification

The advantages of gasification over incineration have been recognized for decades. Gasification yields over 30% more energy than incineration and does not form hazardous pollutants.

Gasification’s successful application in waste to energy systems requires completely converting organic matter into clean syngas. Syngas is a mixture of energy rich combustible gases that can be used to power electrical generator engines or recombined to form liquid fuels.

Incomplete conversion of organic matter into syngas has two major problems.

1. It leaves behind charred residues that contain hazardous materials.

2. It produces tar vapors that contaminate the syngas and condense on surfaces.

Charred material contaminating the ash make it toxic and unacceptable for use in concrete. Tar aerosols can obstruct internal surfaces of apparatus and damage engines and equipment. Residual char and tar contaminants are unacceptable, but they are very costly to remove. It is better to not have either. Hundreds of attempts have been made to solve these problems.

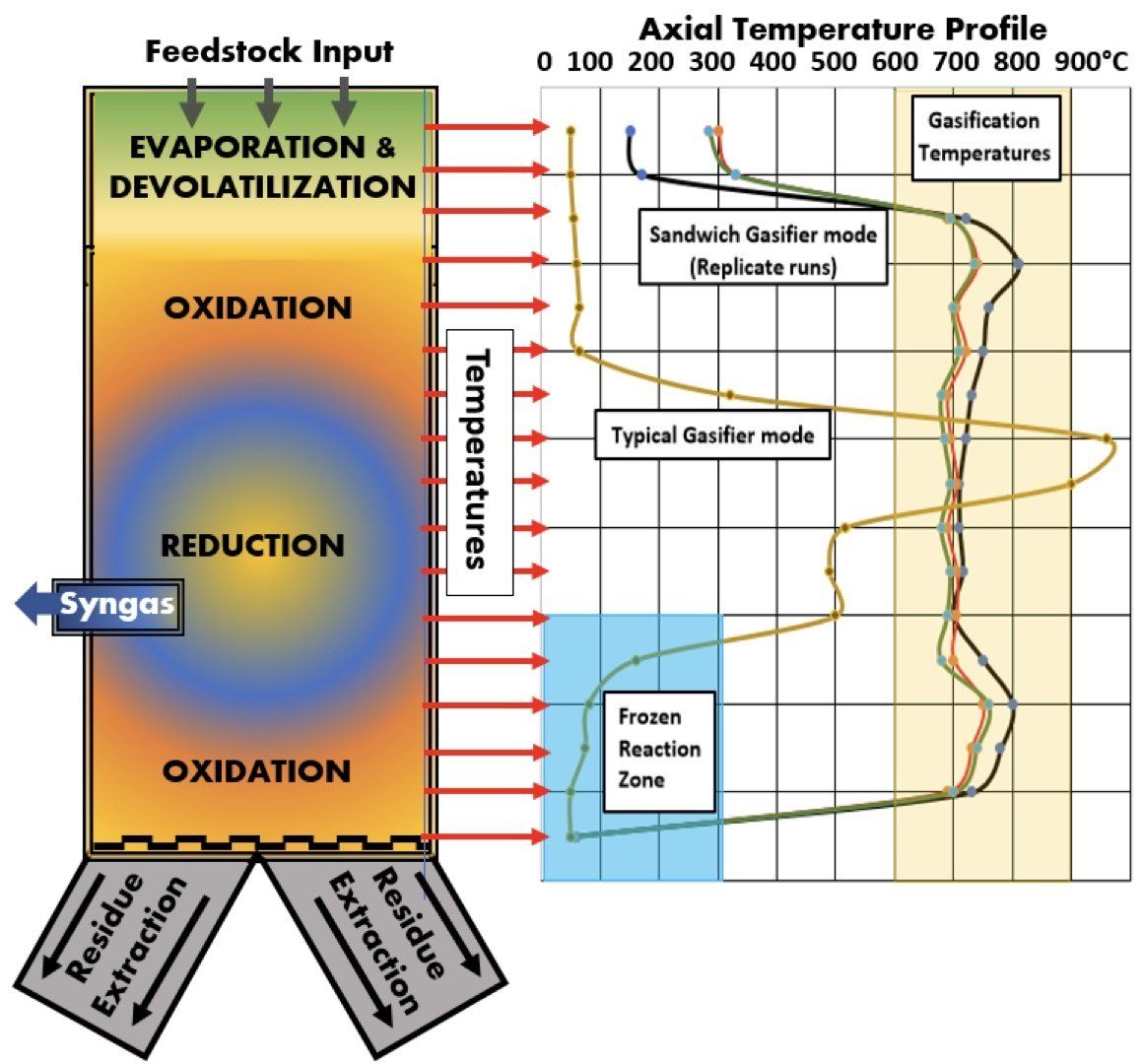

Smart Gasifiers Recycle at the Molecular Level

The Smart Gasifier was invented & patented by Dr. Nikhil Patel, founder and C.E.O. of Singularity Energy Technologies (SET). See: https://www.singularet.com/ for more information.

It is named for the unique configuration of its reaction zones which control heat to efficiently complete gasification of materials of variable compositions (e.g., wet vs. dry; high vs. low energy content), thus maximizing production of clean syngas while minimizing the creation of tar aerosol contaminants and unconverted char residues. Temperature regulation and control of material flow through the system also limit formation of clinkers in the ash.

The syngas is used to fuel electrical generator engines or injected into Fischer-Tropsch reactors to form liquid fuels (i.e., methanol, gasoline, diesel, jet fuel), lubricants, or other products. Production of clean syngas minimizes maintenance downtime while increasing throughput, thus maximizing output of electricity and/or liquid fuels, etc.

For more information about Smart Gasifiers, see the Singularity Energy Technologies website: https://www.singularet.com/

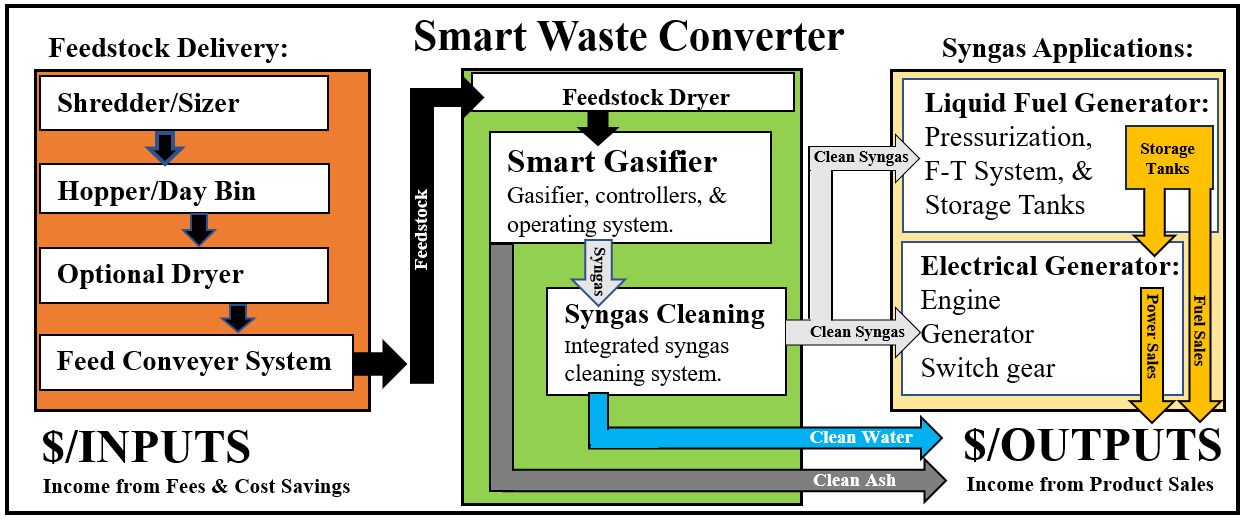

Smart Gasifier Components and Material Flows

Effective gasification is long awaited, and the technologies that process syngas are well established. Fischer-Tropsch (F-T) converters have been in use since the 1930’s, its components are essentially off the shelf. System optimization involves proper matching of system component capacities with Smart Gasifiers outputs to optimize performance.

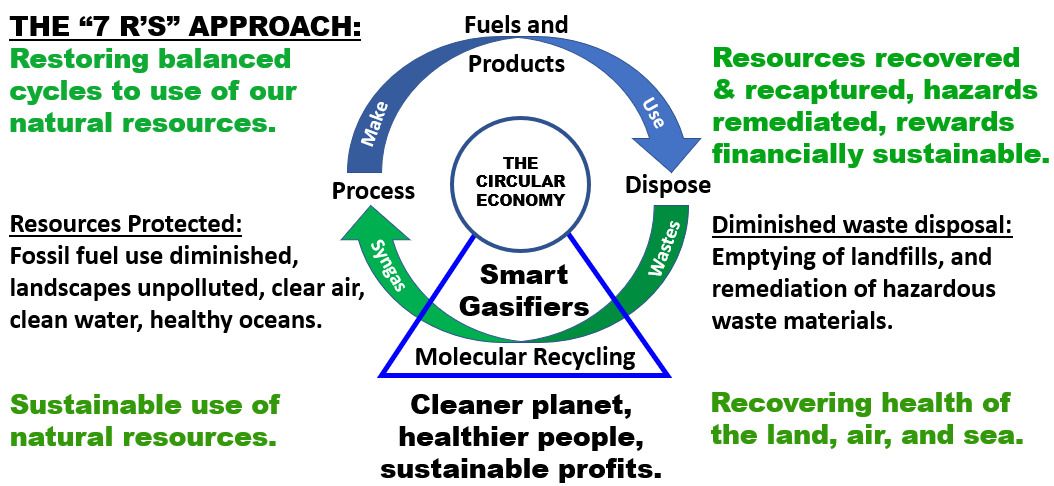

The 7-R's of Resilient Sustainability

- Reduce (resources saved now are ones we will still have later)

- Reuse (most disposable items have reusable alternatives available)

- Recycle (certain items and materials could and should be repeatedly used)

- Recover (value from materials that would otherwise be tossed into landfills)

- Recapture (energy from wastes that have been sitting in landfills for years)

- Remediate (hazardous organic contaminants can be turned into clean syngas)

- Reward (those that perform these tasks need economic sustainability)